Get started, planning your project with Powersystems

Speak with one of our high voltage electrical engineering specialists today.

The selection of the correct protection and control scheme is fundamental to the operation of electrical systems under normal and fault conditions.

Powersystems engineers understand this and will design the optimum system to interface between all the components of an individual site.

We have wide-ranging experience in designing protection schemes for demand and generation connections.

We also understand the intricacies of different types of generation and loads, having designed and installed numerous protection scheme for wind farms, solar parks, hydro schemes, synchronous generation, STATCOMs, rotating stabilisers, and industrial loads.

Using this knowledge, we are able to design, install, and test protection schemes right from concept through to final commissioning.

Firstly, we will select and specify appropriate protection relays, taking into account the reliability and performance requirements of the scheme; the interface between protection relays and the site supervisory control and data acquisition (SCADA) infrastructure; the ability to test and maintain relays throughout the lifetime of the site; and considering the most economical and value-for-money solutions.

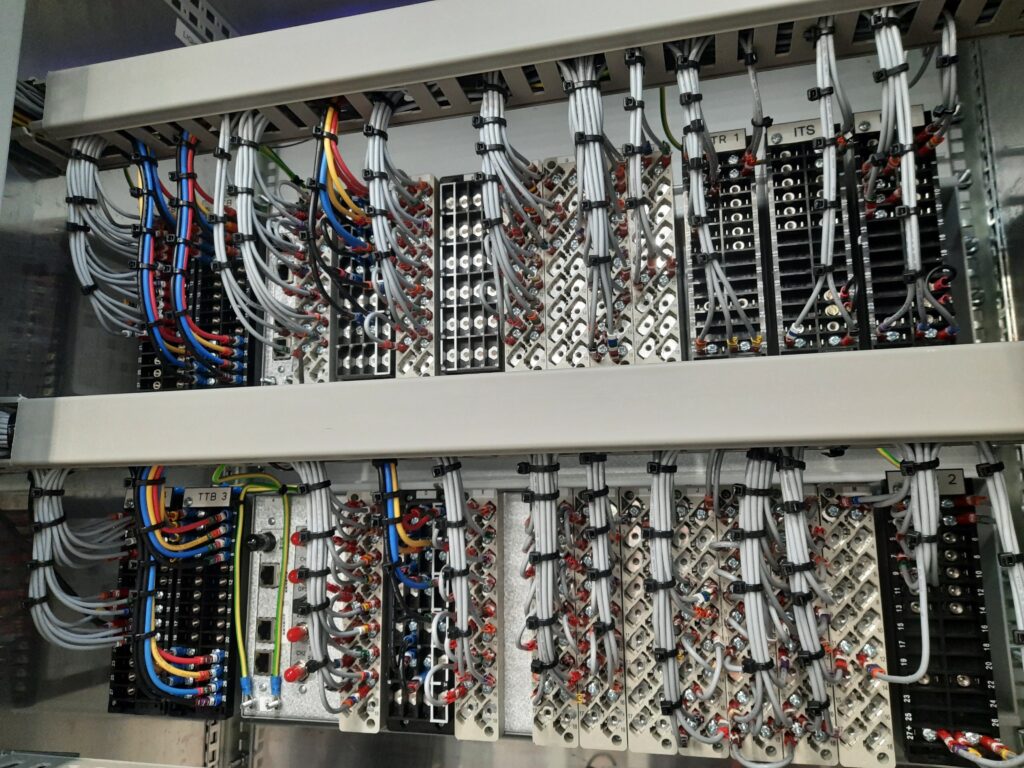

Secondly, we will design the secondary control and protection wiring that interfaces with the relays. Our protection relays can be incorporated into the HV switchgear or installed in custom-built protection and control panels which we design and assemble in-house.

Where we are providing custom protection panels, our CAD design engineers will prepare the AC and DC wiring schematics that are used for assembly of the panels.

Or if we are incorporating relays into the HV switchgear, our engineers will thoroughly review the switchgear manufacturer’s schematics to ensure they incorporate proven principles to increase the reliability of the scheme such as:

Our protection panel schematics are designed in accordance with ENA TS 50-19 Issue 2 – Standard numbering for small wiring, to ensure the wiring can be easily identified and tested.

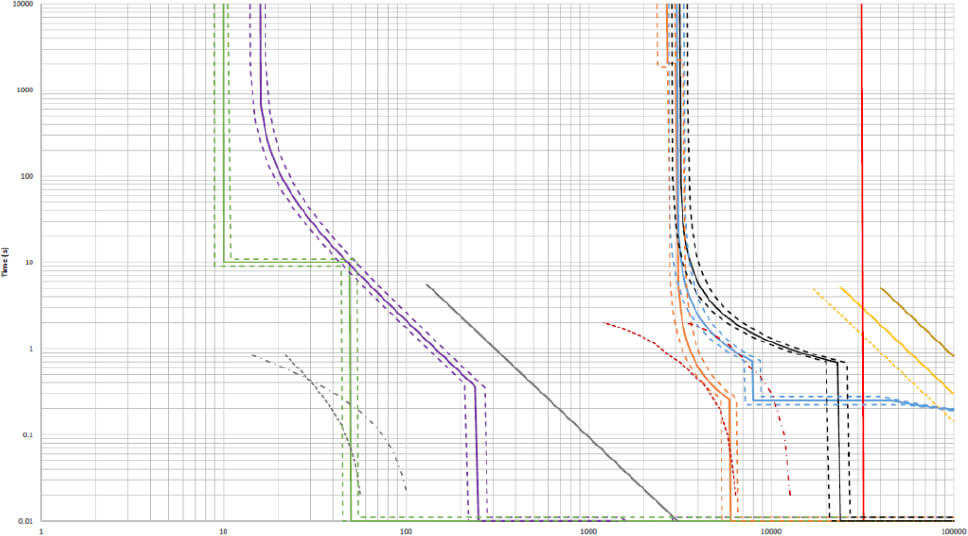

Next, we will carry out protection co-ordination studies to determine appropriate protection settings which will safeguard your plant from damage, whilst considering the need for appropriate discrimination to identify the location of faults, and the need to avoid spurious trips to ensure your plant is online and operational as much as possible.

Our co-ordination study will ensure fault clearance times meet the distribution and transmission standards, and that the plant remains operational within the voltage and frequency limits defined in Engineering Recommendation G99 and the Grid Code.

Once the protection settings have been determined, our engineers will program the protection relays. We have experience applying protection settings and logic to numerous IEDs covering all the common brands such as ABB, GE Multlin, the Schneider / GE MiCOM range, Sepam, Siprotec, SEL, VIP 300/400, and the Siemens Reyrolle range.

Within the IED logic we can interface with other relays on the site using communication protocols such as IEC 61850, DNP3, and Modbus.

Finally, we will test and commission the scheme on site to prove correct operation. We will carry out the full suite of required commissioning including, secondary injection testing of relays; primary injection testing; functional testing; and proving of all signals back to your central SCADA system.

In summary, Powersystems engineers have extensive experience in specifying and installing the following protection and control panel schemes from 11 kV to 132 kV:

Speak with one of our high voltage electrical engineering specialists today.